Glass Ball Lens

- Home

- Balls & Hemispheres

- glass Ball Lens / Glass Ball

Glass ball lenses are spherical optical components made from high-quality glass materials, known for their exceptional clarity and precision. These lenses are integral to various optical applications, offering unmatched performance in focusing and collimating light.

Key Features of Glass Ball Lenses

High Optical Clarity: Made from materials such as fused quartz and engineered optical glass, our glass ball lenses provide excellent transparency and minimal light distortion.

Precision Manufacturing: Each lens is meticulously crafted and polished to achieve a perfect spherical shape, ensuring consistent performance across applications.

Durability: With high resistance to thermal and chemical influences, these lenses maintain their integrity under extreme conditions.

Versatile Applications: Suitable for a wide range of uses, from fiber optic communications to medical instruments and laser systems.

Manufacturing Process

The production of glass ball lenses involves several critical steps to ensure the highest quality:

Material Preparation: Using premium optical glass with a refractive index between 1.5 and 1.7, ensuring high clarity and performance.

Shaping and Rough Grinding: Initial shaping with mechanical tools followed by rough grinding to form an approximate sphere.

Precision Grinding: Fine grinding with advanced machinery to achieve the desired spherical precision.

Polishing: Enhancing surface quality and reducing optical roughness through meticulous polishing techniques.

Coating: Applying optical coatings, such as anti-reflective films, to improve performance by enhancing light transmission and reducing reflections.

Inspection and Testing: Rigorous testing for diameter accuracy, refractive index, transmittance, and overall quality to ensure each lens meets stringent standards.

Cleaning and Packaging: Final cleaning and packaging in a controlled environment to prevent contamination and damage.

Applications of Glass Ball Lenses

Fiber Optic Communications: Enhancing signal coupling efficiency between fibers, emitters, and detectors.

Medical Instruments: Used in endoscopes and ophthalmic surgery for precise light control and imaging.

Laser Systems: Optimizing laser beam transmission and focusing in industrial and scientific applications.

Imaging Devices: Integral components in cameras, microscopes, and telescopes, improving image clarity and reducing distortion.

Barcode Scanning: Essential in laser scanning systems for accurate and efficient barcode reading.

Optical Sensors: Adjusting incident light to enhance sensor sensitivity and accuracy.

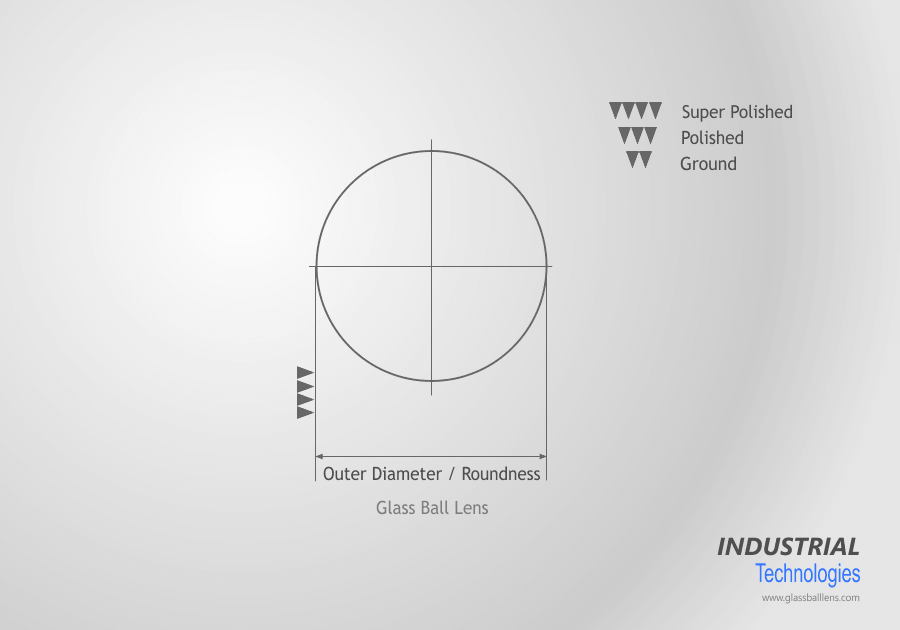

Quality Indicators

Diameter: Accurate measurement ensures optimal fit and performance.

Refractive Index: Determines light propagation speed and image quality.

Transmittance: High transmittance rates for better light passage and system efficiency.

Effective and Back Focal Length: Critical for precise light focusing and collimation.

Numerical Aperture: Higher values indicate superior light collection and imaging capabilities.

Why Choose Our Glass Ball Lenses?

Unmatched Quality: Produced from top-grade materials and subjected to rigorous quality control

Versatility: Suitable for diverse applications across various industries.

Expert Craftsmanship: Leveraging advanced manufacturing techniques and expertise to deliver superior optical components.

Standard Specification of our Glass Ball lenses:

- Tolerance on Glass Ball Lens Diameter

+/- 0.001mm

- Glass Ball Lens Surface Finish in Ra

1.2 nm

- Glass Ball Lens Roundness

< 0.001mm

- No Scratch dig on Glass Ball Lens

at 20X magnification

- Glass Ball Lens Cleaning

Class 100 clean room

- Glass Ball Lens Packing

in Waffle trays or Glass bottles

- Each Glass Ball Lens is checked

100% under microscope before Delivery.

- All Glass Ball Lenses are cleaned and packed

in Class 100 clean room area.

Ball Lens Products from other materials

Glass Ball Lens / Glass Ball

We Manufacture Glass ball lenses range in diameter from 0.40mm to 8.0mm.

Half Ball Lens / Hemispheres

Half ball lenses are made from a wide variety of optical glasses with refractive index ranging from 1.50 to 2.10.

Low Tg Ball Lens

Industrial Technologies manufactures Low Tg ball lenses range in diameter from 0.40mm to 8.0mm.

High Index Glass Ball

With higher coupling efficiency required for Transmitters and Receivers, it is becoming more and more popular.

Saphire / Sapphire Ball

Sapphire is one of hardest known material with consistent quality available on a commercially economical scale.

Spinel Ball

Spinel is also a well known single crystal being used in the optical industry. The main advantage being that spinel is a cubic single crystal.

Ceramic Ball

Alumina oxide balls resist corrosion and abrasion extremely well and maintain dimensional stability at temperatures up to 1734ºC (3180 ºF).

Cubic Zirconia Ball

The high refractive index of Cubic Zirconia material makes it very interesting to be used as a Ball lens for optical telecom products.

Glass Rods

We manufacture glass rods from diameter ranging from 0.60mm to 8.00mm in length ranging from 5.00mm to 100.00mm.

Glass Rod Preforms

Glass rods can be used as preforms for glass molding application as well.

Rod Preforms

Rod Preforms are manufacture from renowned optical glass material makers like OHARA, HIKARI, SUMITA, SCHOTT, etc.

Quartz Ball Lens

Quartz ball lens with good UV and IR transmission is widely used for focusing and coupling light into and out of the fibre.

AR coated ball lens

Our AR coated ball lenses are precisely & uniformly coated all over the surface.

Looking for Ball Lens? Submit your requirements get a free Quote