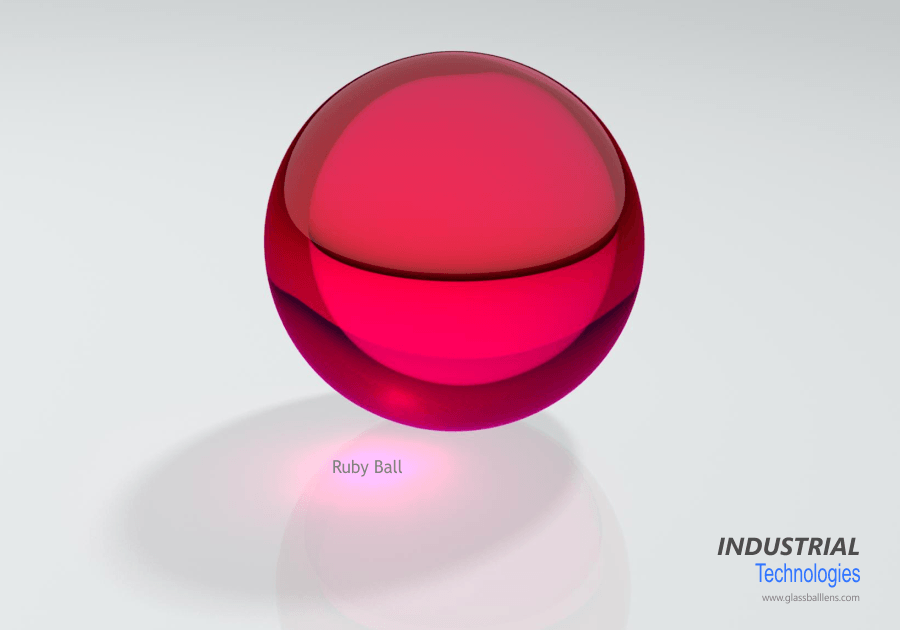

Ruby Ball

- Home

- Balls & Hemispheres

- Ruby Ball

Ruby balls are meticulously crafted from synthetic ruby, known for its exceptional hardness and precision. These robust spheres are integral to various industrial and technological applications due to their unparalleled durability and resistance to wear and tear.

Key Features

Superior Hardness: Ruby balls rank just below diamonds on the Mohs hardness scale, making them highly resistant to scratches and abrasions.

Thermal Stability: With a melting point over 2000°C, ruby balls can withstand extreme temperatures, making them ideal for high-heat environments.

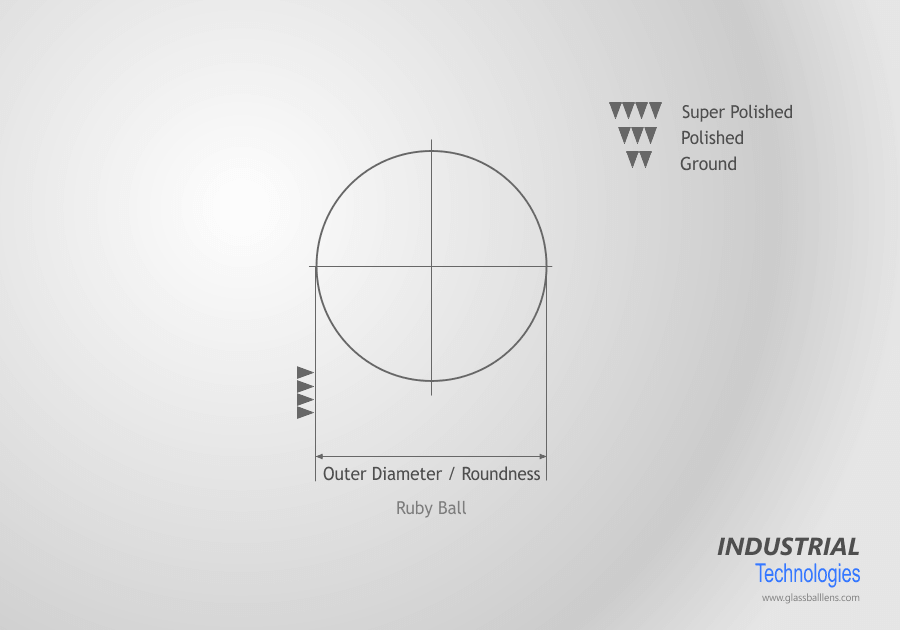

Precision Engineering: Each ruby ball is manufactured to exacting standards, ensuring consistent diameter and sphericity. This precision minimizes wear and tear, prolonging the product's lifespan.

Chemical Resistance: Ruby balls offer excellent resistance to acids and bases, making them suitable for use in harsh chemical environments.

Applications

Optical Instruments: Ruby balls are used in high-end optical devices due to their clarity and minimal light distortion.

Jewel Bearings: Essential in high-precision machinery, jewel bearings made from ruby balls reduce friction and enhance durability, commonly found in luxury watches.

Technical Storage Systems: Ruby balls help manage heat and improve efficiency in advanced storage solutions.

Industrial Machinery: From semiconductors to aerospace applications, ruby balls provide reliable performance under demanding conditions.

Product Range

Our ruby balls are available in a variety of sizes to meet diverse application needs:

Small (1mm - 3mm): Ideal for compact spaces like micro-machinery and precision watches.

Medium (4mm - 8mm): Versatile for optical instruments and precision engineering tools.

Large (10mm - 16mm): Suitable for heavy-duty industrial equipment and advanced aerospace applications.

Why Choose Our Ruby Balls?

Swiss-Grade Quality: Sourced from the most reliable suppliers, our ruby balls are crafted with exceptional attention to detail.

Rigorous Testing: Each ball undergoes stringent testing to ensure size accuracy, polish level, and overall quality.

Clean Room Packaging: To maintain purity and quality, all ruby balls are cleaned and packed in a Class 100 clean room environment.

Ball Lens Products from other materials

Glass Ball Lens / Glass Ball

We Manufacture Glass ball lenses range in diameter from 0.40mm to 8.0mm.

Half Ball Lens / Hemispheres

Half ball lenses are made from a wide variety of optical glasses with refractive index ranging from 1.50 to 2.10.

Low Tg Ball Lens

Industrial Technologies manufactures Low Tg ball lenses range in diameter from 0.40mm to 8.0mm.

High Index Glass Ball

With higher coupling efficiency required for Transmitters and Receivers, it is becoming more and more popular.

Saphire / Sapphire Ball

Sapphire is one of hardest known material with consistent quality available on a commercially economical scale.

Spinel Ball

Spinel is also a well known single crystal being used in the optical industry. The main advantage being that spinel is a cubic single crystal.

Ceramic Ball

Alumina oxide balls resist corrosion and abrasion extremely well and maintain dimensional stability at temperatures up to 1734ºC (3180 ºF).

Cubic Zirconia Ball

The high refractive index of Cubic Zirconia material makes it very interesting to be used as a Ball lens for optical telecom products.

Glass Rods

We manufacture glass rods from diameter ranging from 0.60mm to 8.00mm in length ranging from 5.00mm to 100.00mm.

Glass Rod Preforms

Glass rods can be used as preforms for glass molding application as well.

Rod Preforms

Rod Preforms are manufacture from renowned optical glass material makers like OHARA, HIKARI, SUMITA, SCHOTT, etc.

Quartz Ball Lens

Quartz ball lens with good UV and IR transmission is widely used for focusing and coupling light into and out of the fibre.

AR coated ball lens

Our AR coated ball lenses are precisely & uniformly coated all over the surface.

Looking for Ball Lens? Submit your requirements get a free Quote